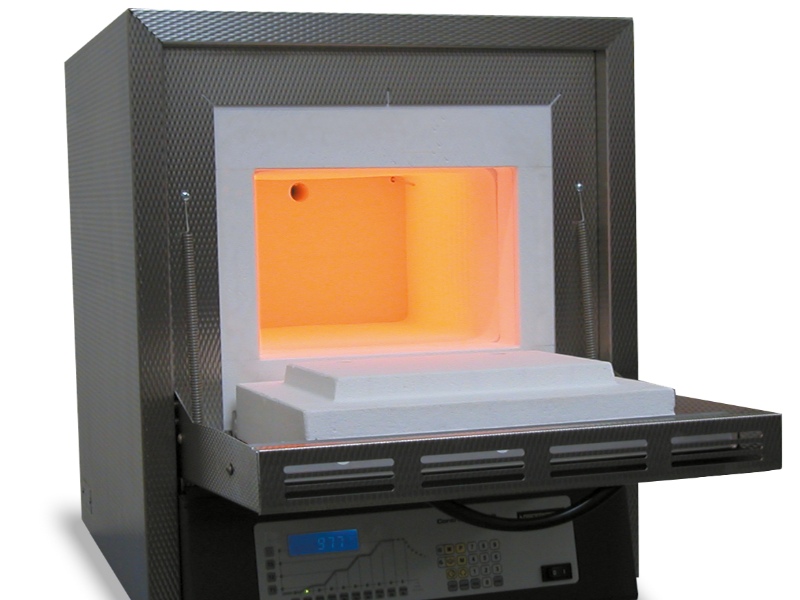

Nabertherm muffle Furnaces

High-Quality Muffle Furnaces for Laboratory Applications

Our Nabertherm muffle furnace range offers reliable and high-performance solutions for laboratories performing heat treatment, ashing, and combustion loss analysis. With models supporting temperatures up to 3000 °C, chamber volumes ranging from 3 to 60 liters, and advanced options like integrated weighing systems, 4-sided ceramic heating, and real-time data logging, these furnaces are engineered for accuracy, efficiency, and long-term durability.

Designed with scientific workflows in mind, each unit features rapid heat-up times, modern touchscreen control systems, and robust construction tailored to withstand demanding use. Whether you’re conducting material testing, sample pre-treatment, loss on ignition (LOI), or advanced thermogravimetric analysis (TGA), Nabertherm muffle furnaces deliver repeatable and uniform results. These units are built to comply with ISO, ASTM, and DIN protocols, making them ideal for use in quality control labs, academic research, and industrial R&D environments.

Standard Muffle Furnaces – L and LT Series (up to 1100 °C)

The Nabertherm L and LT series are robust laboratory muffle furnaces suitable for a wide range of heat treatment applications. They offer maximum temperatures of 1100 °C, chamber volumes from 3 to 40 liters, and come with either a flap door (L) or lift door (LT). These models feature heating from two sides, and an efficient insulation design for rapid heat-up times. Ideal for general purpose lab work requiring repeatable and stable heat processing.

- Max. temperature: 1100 °C

- Chamber volume: 5 liters

- Internal dimensions: 205 × 170 × 130 mm

- Heat-up time: approx. 47 min to 1100 °C

- Insulated flap door for use as work surface

€4.120,00 Original price was: €4.120,00.€3.872,80Current price is: €3.872,80. excl. VAT

- Tmax 1100 °C for laboratory heat treatment

- 9-liter chamber volume

- Inner dimensions: 235 × 240 × 170 mm

- Heat-up time to Tmax: approx. 63 minutes

- 1-phase power, 3.3 kW, 35 kg unit weight

€4.350,00 Original price was: €4.350,00.€4.089,00Current price is: €4.089,00. excl. VAT

- Tmax 1100 °C for laboratory heat treatment

- 15-liter chamber volume

- Inner dimensions: 230 × 340 × 170 mm

- Heat-up time to Tmax: approx. 74 minutes

- 1-phase power, 3.5 kW, 43 kg unit weight

€5.120,00 Original price was: €5.120,00.€4.812,80Current price is: €4.812,80. excl. VAT

- Tmax 1100 °C for laboratory heat treatment

- 24-liter chamber volume

- Inner dimensions: 280 × 340 × 250 mm

- Heat-up time to Tmax: approx. 69 minutes

- 3-phase power, 4.9 kW, 52 kg unit weight

€5.760,00 Original price was: €5.760,00.€5.414,40Current price is: €5.414,40. excl. VAT

- Tmax 1100 °C for laboratory heat treatment

- 40-liter chamber volume

- Inner dimensions: 320 × 490 × 250 mm

- Heat-up time to Tmax: approx. 80 minutes

- 3-phase power, 6.5 kW, 70 kg unit weight

€7.110,00 Original price was: €7.110,00.€6.683,40Current price is: €6.683,40. excl. VAT

Compact Economic Furnaces – LE Series

The LE series provides a cost-effective solution for labs seeking Nabertherm reliability with fewer frills. Available with chamber sizes from 1 to 24 liters, these units are designed for straightforward thermal processes up to 1100 °C. Their compact design, fast heating, and simple operation make them perfect for routine lab applications, materials testing, and education settings.

- Max. temperature: 1100 °C

- Chamber volume: 2 liters

- Internal dimensions: 110 × 180 × 120 mm

- Heat-up time: approx. 25 min to 1100 °C

- Flap door functions as loading surface

€2.240,00 Original price was: €2.240,00.€2.105,60Current price is: €2.105,60. excl. VAT

- Max. temperature: 1100 °C

- Chamber volume: 6 liters

- Internal dimensions: 170 × 200 × 170 mm

- Heat-up time: approx. 30 min to 1100 °C

- Flap door functions as loading surface

€2.740,00 Original price was: €2.740,00.€2.575,60Current price is: €2.575,60. excl. VAT

- Max. temperature: 1100 °C

- Chamber volume: 14 liters

- Internal dimensions: 220 × 300 × 220 mm

- Heat-up time: approx. 35 min to 1100 °C

- Flap door functions as loading surface

€3.340,00 Original price was: €3.340,00.€3.139,60Current price is: €3.139,60. excl. VAT

- Max. temperature: 1100 °C

- Chamber volume: 24 liters

- Internal dimensions: 260 × 330 × 280 mm

- Heat-up time: approx. 45 min to 1100 °C

- Flap door functions as loading surface

€4.610,00 Original price was: €4.610,00.€4.333,40Current price is: €4.333,40. excl. VAT

Advanced Ceramic Muffle Furnaces – L SKM Series

Designed for labs working with aggressive vapors and corrosive atmospheres, the L SKM series features a ceramic muffle with embedded heating from four sides, ensuring excellent temperature uniformity and protecting heating elements. These models are ideal for clean processes, with smooth, nearly particle-free inner surfaces. Available in flap (L) and lift door (LT) versions, they combine high thermal resistance with enhanced operator safety.

- Tmax 1100 °C for demanding lab applications

- 9-liter ceramic muffle chamber

- Inner dimensions: 230 × 240 × 170 mm

- Heat-up time to Tmax: approx. 75 minutes

- 1-phase power, 3.7 kW, 50 kg unit weight

€5.930,00 excl. VAT

- Tmax 1100 °C for laboratory heat treatment

- 9-liter ceramic muffle chamber

- Inner dimensions: 230 × 240 × 170 mm

- Heat-up time to Tmax: approx. 75 minutes

- 1-phase power, 3.7 kW, 50 kg unit weight

€5.930,00 excl. VAT

Ashing Furnaces – LV and LVT Series

The LV and LVT series are dedicated ashing furnaces, designed to meet the high oxygen and exhaust air demands of loss on ignition (LOI) and material decomposition processes. Operating up to 1100 °C, these units achieve over 6 air exchanges per minute and offer preheated incoming air for excellent uniformity. Chamber sizes range from 3 to 15 liters, with ceramic heating plates and airflow optimized for fast, clean combustion. Available with flap (LV) or lift door (LVT).

- Tmax 1100 °C for standardized ashing procedures

- 3-liter chamber with ceramic heating plates

- Inner dimensions: 180 × 150 × 120 mm

- Heat-up time to Tmax: approx. 45 minutes

- 1-phase power, 1.3 kW, 20 kg unit weight

€3.820,00 excl. VAT

- Tmax 1100 °C for standardized ashing procedures

- 5-liter chamber with ceramic heating plates

- Inner dimensions: 205 × 170 × 130 mm

- Heat-up time to Tmax: approx. 55 minutes

- 1-phase power, 2.6 kW, 29 kg unit weight

€4.780,00 excl. VAT

- Tmax 1100 °C for standardized ashing procedures

- 9-liter chamber with ceramic heating plates

- Inner dimensions: 235 × 240 × 170 mm

- Heat-up time to Tmax: approx. 70 minutes

- 1-phase power, 3.3 kW, 36 kg unit weight

€5.330,00 excl. VAT

- Tmax 1100 °C for standardized ashing procedures

- 15-liter chamber with ceramic heating plates

- Inner dimensions: 230 × 340 × 170 mm

- Heat-up time to Tmax: approx. 80 minutes

- 1-phase power, 3.6 kW, 44 kg unit weight

€6.450,00 excl. VAT

Weighing Furnaces – L and LT SW Series with Integrated Scale & Software

The SW series integrates a precision scale, ceramic plunger, and VCD software into the muffle furnace for real-time combustion loss measurement. Available with flap (L) or lift (LT) doors, these 9-liter units reach up to 1100 °C or 1200 °C depending on model. Ideal for laboratories performing thermogravimetric analysis (TGA) of sludge, waste, and biomass. Software logs temperature and mass loss continuously for audit-ready documentation.

- Tmax 1100 °C with 9-liter chamber

- Built-in scale and software for combustion loss

- Inner dimensions: 230 × 240 × 170 mm

- Heat-up time to Tmax: approx. 65 minutes

- 1-phase power, 3.3 kW, 50 kg unit weight

€9.320,00 excl. VAT

- Tmax 1200 °C for advanced combustion testing

- 9-liter chamber with integrated scale & software

- Inner dimensions: 230 × 240 × 170 mm

- Heat-up time to Tmax: approx. 75 minutes

- 1-phase power, 3.3 kW, 50 kg unit weight

€10.660,00 excl. VAT

Did not found what you were looking for?

Not all available models are displayed on this page. Nabertherm offers a wide range of muffle furnaces, including custom configurations, optional accessories, and advanced control systems. Discover our full Nabertherm laboratory catalog.

Frequently asked questions about muffle furnaces

What is a muffle furnace used for in laboratories?

A muffle furnace is used for high-temperature applications such as ashing, annealing, sintering, and combustion loss determination. It ensures uniform, controlled heating in a closed chamber.

What temperature ranges do Nabertherm muffle furnaces support?

Nabertherm furnaces typically operate up to 1100 °C or 1200 °C, depending on the model range. For more extended applications, solutions are available up to 3000°C.

What's the difference between L and LT models?

L models come with a flap door, which can be used as a loading shelf, while LT models have a lift door that directs heat away from the operator during opening.

Can these furnaces be used with aggressive substances?

Yes. The SKM models feature a ceramic muffle and 4-sided heating, offering protection from corrosive vapors and particles.

Which models are suitable for ashing and LOI?

The LV and LVT series are engineered for ashing processes, offering over 6 air exchanges per minute and precise temperature control.

Do any models include combustion loss measurement tools?

Yes. The L(SW) and LT(SW) models come with an integrated scale and software for live tracking of combustion loss during heating cycles.

What chamber sizes are available?

Nabertherm standard muffle furnaces come in sizes ranging from 1 liters to 60 liters, depending on the model and application.

Are all furnaces compatible with programmable controllers?

Yes. All models include a modern touchscreen B510 controller as standard, allowing multiple-step programming and temperature ramps. More advanced features are available with the optional C550 controller.