Laboratory Vacuum Ovens

Labman Instruments is official distributor for Binder and Jeiotech vacuum ovens for Belgium, Netherlands and Luxembourg.

Reliable Vacuum Drying Ovens for Heat-Sensitive Materials

Vacuum ovens are essential in laboratories and industrial environments where sensitive materials must be dried under reduced pressure and at low temperatures. This method not only preserves the integrity of temperature-sensitive substances but also accelerates the drying process by lowering the boiling point of solvents.

As a leading manufacturer of high-quality lab equipment, Binder offers a comprehensive range of vacuum ovens designed for both non-flammable and flammable solvents. The Binder VD series is optimized for precise, gentle drying in standard laboratory settings, while the Binder VDL series is fully ATEX-compliant, making it ideal for safely processing materials containing flammable solvents.

All Binder VD and VDL ovens are equipped with advanced safety features, user-friendly touchscreen controls, and patented aluminum expansion racks that ensure uniform heat transfer and efficient process control. Whether your application is in pharmaceuticals, chemistry, electronics, or materials science, Binder vacuum ovens deliver the performance and reliability required for demanding laboratory workflows.

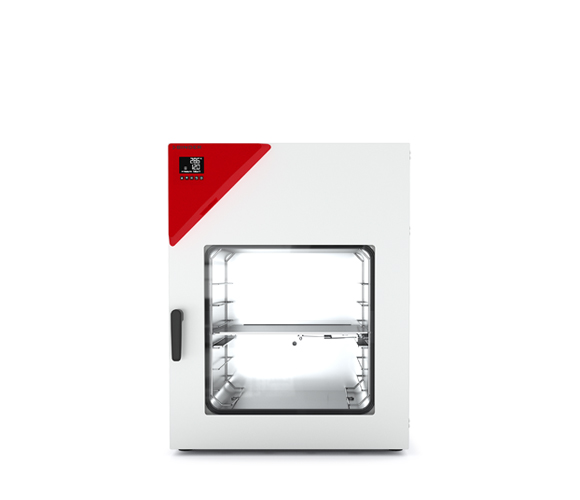

Binder VD series for non-flammable product drying

The Binder VD vacuum oven series is engineered for the gentle, precise drying of sensitive materials and samples with non-flammable solvents. Featuring patented aluminum expansion racks for optimal heat transfer and digital process control, these ovens deliver reliable performance for routine laboratory applications. Ideal for research, materials testing, and quality control labs that demand accuracy and reproducibility.

- Volume: 24 liter

- Products: non-flammable

- Standard expansion racks: 1/4

- End point detection: yes

- Door: large viewing window

Price on request

- Volume: 55 liter

- Products: non-flammable

- Standard expansion racks: 1/5

- End point detection: yes

- Door: large viewing window

Price on request

- Volume: 119 liter

- Products: non-flammable

- Standard expansion racks: 1/6

- End point detection: yes

- Door: large viewing window

Price on request

Binder VDL Atex series for flammable product drying

The Binder VDL series is your trusted solution when safety is paramount. These ATEX-certified vacuum ovens are specially designed for drying materials containing flammable solvents. With explosion-proof components, integrated safety systems, and inert gas connections, the VDL series provides the highest level of protection without compromising on drying performance. Perfect for use in pharmaceutical, chemical, and industrial labs with elevated safety standards.

- Volume: 119 liter

- Products: flammable

- Standard expansion racks: 2/6

- End point detection: yes

- Door: large viewing window

Price on request

- Volume: 24 liter

- Products: flammable

- Standard expansion racks: 2/4

- End point detection: yes

- Door: large viewing window

Price on request

- Volume: 55 liter

- Products: flammable

- Standard expansion racks: 2/5

- End point detection: yes

- Door: large viewing window

Price on request

Jeiotech OV Series – Compact and Economical Drying Solutions

Jeiotech offers a complete range of compact, affordable vacuum ovens ideal for research, quality control, and small-batch production. Available in standard and “S” models with enhanced stability, these ovens are well-suited for gentle drying of heat-sensitive or oxidizable materials.

- End point determination: manual

- Chamber volume: 28 L

- Temp. range: Ambient +27°C to 250°C

- Control: 3.5-inch digital PID controller

- Highlights: Compact size, rapid heating, durable build

€3.900,00 excl. VAT

- End point determination: manual

- Chamber volume: 28 L

- Temp. range: Ambient +15°C to 250°C

- Vacuum level: Rapid drying under reduced pressure

- Highlights: PID control, double glass window

€4.390,00 excl. VAT

- End point determination: manual

- Chamber volume: 65 L

- Temp. range: Ambient +27°C to 250°C

- Control: 3.5-inch digital PID controller

- Highlights: Large capacity, precise control, durable design

€4.860,00 excl. VAT

- End point determination: manual

- Chamber volume: 65 L

- Temp. range: Ambient +15°C to 250°C

- Vacuum level: Gentle drying under reduced pressure

- Highlights: PID control, large capacity

€5.464,00 excl. VAT

Frequently asked questions

What is a vacuum oven, and how does it work?

A vacuum drying oven is a laboratory device used to dry heat-sensitive or solvent-laden materials under reduced pressure. By lowering the ambient pressure inside the chamber, vacuum ovens allow solvents to evaporate at lower temperatures, protecting delicate samples and reducing drying time.

What are the benefits of using a Binder vacuum drying oven?

Binder ovens are known for their precise temperature control, durable construction, and unique heat transfer technology. They offer intuitive touchscreen operation, internal data logging, and seamless stainless steel chambers for easy cleaning. The patented aluminum racks ensure even heat distribution, making Binder VD ovens ideal for high-quality, reproducible drying results.

What’s the difference between Binder VD and VDL series?

The VD series is designed for use with non-flammable solvents, offering efficient and safe drying for routine applications. The VDL series is ATEX-certified, meaning it meets stringent safety requirements for handling flammable solvents, including integrated overpressure protection, explosion-proof components, and inert gas purging options.

What does ATEX certification mean for a vacuum oven?

ATEX certification ensures that a device can be safely used in environments where explosive atmospheres may be present. Binder VDL vacuum ovens are designed according to ATEX directives, offering protection against ignition risks when drying materials with flammable solvents.

Can Binder vacuum ovens be connected to inert gas sources?

Yes, all Binder VD and VDL models include inert gas connections, allowing for nitrogen or other inert gas purging. This enhances safety and reduces oxidation during the drying process.

What sizes are available for Binder vacuum ovens?

Binder vacuum ovens are available in multiple chamber volumes:

VD/VDL 23: 24 liters

VD/VDL 56: 55 liters

VD/VDL 115: 119 liters

This variety allows users to choose the right capacity for their specific laboratory needs.

Are Binder vacuum ovens suitable for pharmaceutical or GMP labs?

Yes, Binder vacuum ovens—especially the ATEX-compliant VDL series—are widely used in pharmaceutical, chemical, and GMP-compliant laboratories. Their precise control systems, documentation capabilities, and hygienic design meet stringent regulatory and safety requirements.

Where can I buy a Binder vacuum oven or request a quote?

As an official distributor of Binder products, we offer expert guidance, technical support, and competitive pricing. You can explore product specifications on our website or contact us directly via our form to request a quote or consultation.