Asem Kristal Fume Hood L1500 – High-End Metal, Class 0, EN14175

Pricing on request

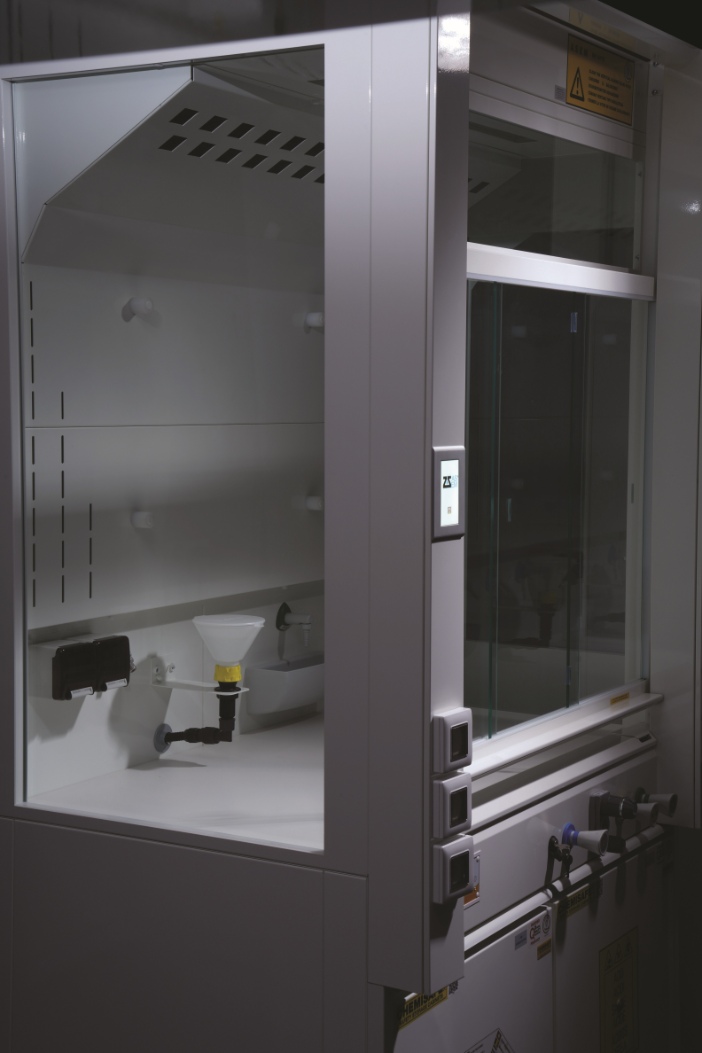

The Asem Kristal L1500 is a premium laboratory fume hood built with a Class 0 fire-resistant steel structure and certified to EN14175 and NFX15-203. It features a vertical sash with laminated glass and anti-fall safety, an integrated sealed technical drawer for utilities, and a double-plenum design for optimized vapour removal. Its modular glazing, IP65 LED lighting, and ergonomic design make it a optimal solution for demanding laboratories.

Asem Kristal L1500 Fume Hood – Premium Safety and Ergonomics

The Kristal L1500 belongs to Asem’s high-end fume cupboard line, engineered for advanced safety, durability, and operator comfort. Built with a Class M0 galvanized steel frame and epoxy coating, it is certified to both EN14175 and NFX15-203 standards, ensuring superior performance and compliance with international regulations.

The sash is equipped with laminated 6 mm safety glass in three sliding panels, with an anti-fall system and counterweights positioned outside the airflow to avoid corrosion. Silent sliding guides, a deflagration ceiling panel, and ergonomic mechanical stops at 30 cm and 45 cm complete its safety-focused design.

A unique feature of the Kristal series is its sealed technical front drawer, which houses utilities, fluid taps, electrical outlets, alarms, and electronics in separate compartments, protected against spills. This design simplifies maintenance and improves long-term reliability.

With a double-plenum system for heavy and light vapours, by-pass and airfoil-pass for turbulence-free airflow, full side glazing for visibility, modular replaceable windows, and IP65 LED lighting, the Kristal L1500 offers the highest level of usability and safety in its category.

Lead time: 8-10 weeks

| Specification | Value |

|---|---|

| External dimensions (W × D × H) | 1565 × 960 × 2300 mm |

| Internal dimensions (W × D × H) | 1500 × 750 × 1230 mm |

| Weight | 240 kg |

| Structure | Full metal, Class M0 |

| Sash | Vertical counterbalanced sash, 3 laminated sliding glass windows |

| Airflow volume at 0.5 m/s | 1035 m³/h |

| Variable volume range | 47–1035 m³/h |

| Economy mode range | 47–697 m³/h |

| Pressure loss | 50 Pa |

| Sash locking height | 450 mm (economy at 300 mm) |

| Lighting | LED, IP65, 800 lux, outside aspiration volume |

| Exhaust collar | Ø 250 mm (Ø 200 mm optional) |

| Utilities | Integrated via sealed front technical drawer |

| Safety | Anti-fall sash system, deflagration ceiling panel, technical separation drawer |

| Supports | Trellis support points Ø 12/13 mm |

- Exhaust collar diameter: Ø 200 mm (instead of Ø 250 mm)

- Side panels: full metal or full-height glazed for maximum visibility

- Worktop materials: stoneware, polypropylene, glass, stainless steel

- Interior lining: stoneware, glass, HPL, polypropylene, stainless steel

- Technical drawer configurations for utilities (gas, water, vacuum, compressed air)

- Motorised sash opening system

- External IP55 sockets integrated in technical drawer

- Airflow control systems (AC1000, AC2000, AC3500, AC7000)

- RMP patented mechanical flow regulation system

- Presence sensor with auto-closing sash

- Under-bench furniture: storage cabinets or chemical safety cabinets