Binder VDL 115 atex vacuum oven

Pricing on request

- Volume: 119 liter

- Temperature range: +9°C above ambient temperature to +110 °C

- ATEX conformity for units: EX II 2/3/- G IIB T3 Gb/Gc/- X

- Intuitive touchscreen controller with graphical pressure and temperature display

- Program-controlled drying monitoring with automatic ventilation at end of process

- Internal data logger, measured values can be read out in open format via USB

- Pressure control device for heating activated from < 100 mbar

- 2 aluminum expansion racks, can be custom-positioned

- Universal connection for ventilation with ambient air or inert gas

- Universal access port DN 16 – for the introduction of external measuring devices

- Shatterproof, spring-mounted safety glass panel

- Large viewing window

- Computer interface: Ethernet

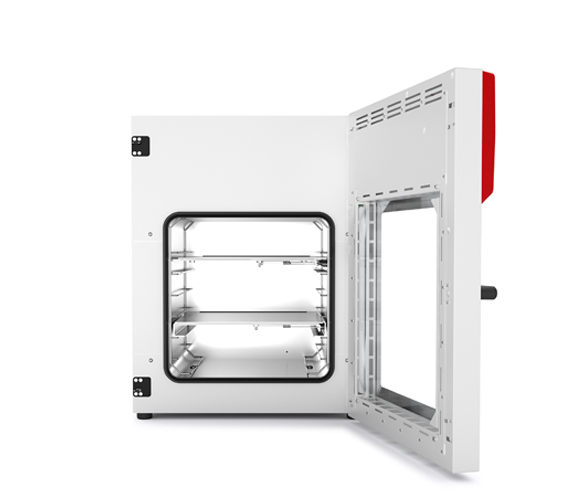

Binder VDL 115 Vacuum Oven – Maximum Safety and Capacity for Drying Flammable Solvents

The Binder VDL 115 vacuum oven is the ideal solution for laboratories that require safe, efficient drying of large volumes of materials containing flammable solvents. With a generous 119-liter chamber and full ATEX compliance, this explosion-proof vacuum oven ensures maximum protection while maintaining the precision and performance BINDER is known for.

Designed for use in pharmaceutical, chemical, and industrial research environments, the VDL 115 combines patented aluminum expansion rack technology, a touchscreen control interface, and an integrated safety system that includes automatic pressure relief, inert gas purging, and real-time monitoring. Its robust construction and advanced safety features make it perfectly suited for handling hazardous substances in regulated settings.

Key Features:

ATEX-Certified for Flammable Solvents: Safe for use in explosive atmospheres

Temperature Range: +9°C above ambient to +110°C

Large 128-Liter Chamber: Supports high-throughput or large-sample drying

Explosion-Proof Safety Design: Includes overpressure relief and flameproof components

Patented Heat Transfer System: Adjustable aluminum shelves for uniform heating

Inert Gas Connection: Enables nitrogen purging for added safety

Touchscreen Controller: Intuitive interface for temperature and vacuum settings

Internal Data Logger: Export process data via USB in open format

Shatterproof Viewing Window: Large glass panel with optional internal lighting

Durable Stainless Steel Interior: Seamless and easy to clean

The Binder VDL 115 offers a best-in-class solution for safe vacuum drying of flammable solvents, combining advanced features with high-volume capability for laboratories with demanding safety and capacity needs.

Warranty: 2 years

Lead time: 1-2 weeks

| Designation | *VDL115-230V |

| Article Number | 9630-0011 |

| Performance Data Temperature | |

| Temperature range | +9 °C above ambient temperature to 110 °C |

| Temperature uniformity at 100°C | 2.9 ± K |

| Temperature fluctuation at 100°C | 0.1 ± K |

| Heating up time to 100°C | 170 min |

| Vacuum Data | |

| Leak rate | 0,01 bar/h |

| Temperature fluctuation over time at 50 mbar | 1 ± mbar |

| Temperature fluctuation over time at 400 mbar | 70 ± mbar |

| Measures | |

| Interior volume | 119 L |

| Net weight of the unit (empty) | 158 kg |

| Load per rack | 20 kg |

| Permitted load | 70 kg |

| Doors | |

| Unit doors | 1 |

| Internal Dimensions | |

| Interior width | 506 mm |

| Interior height | 506 mm |

| Interior depth | 460 mm |

| Wall clearance | |

| Wall clearance back | 100 mm |

| Wall clearance sidewise | 70 mm |

| Housing dimensions not incl. fittings and connections | |

| Width net | 743 mm |

| Height net | 942 mm |

| Depth net | 581 mm |

| Electrical data | |

| Housing protection acc. to EN 60529 | 20 |

| Rated Voltage | 200…230 V |

| Power frequency | 50/60 Hz |

| Nominal power | 1,6 kW |

| Nominal current | 7,0 A |

| Unit fuse | 10,0 A |

| Phase (Nominal voltage) | 1~ |

| Connections | |

| Vacuum connection with small flange | 16 DN mm |

| Measuring access port with small flange | 16 DN mm |

| Universalanschluss für Luft / Inertgas, mit Durchflussbegrenzer (RP”) | 3/8 |

| Environment-specific data | |

| Sound-pressure level | 40 dB(A) |

| Energy consumption at 100°C | 230 Wh/h |

| Fixtures | |

| Number of shelves (std./max.) | 2/6 |

- Touchscreen Controller – Graphical display of main process parameter

- Expansion racks – Choice of aluminum or stainless steel racks depending on the application requirements

- Analogue output for temperature and pressure signals – for external monitoring and evaluation of the process parameters, integration into in house systems is possible

- Universal ventilation – Selection of different ventilation by air or inert gas

- Universal access port DN 40 – for the introduction of external measuring devices

- Multi Management Software APT-COM – Manage, record and document device parameters

- Services – extensive services ensure correct device function