Asem Kristal Fume Hood L1800 – High-End Metal, Class 0, EN14175

Pricing on request

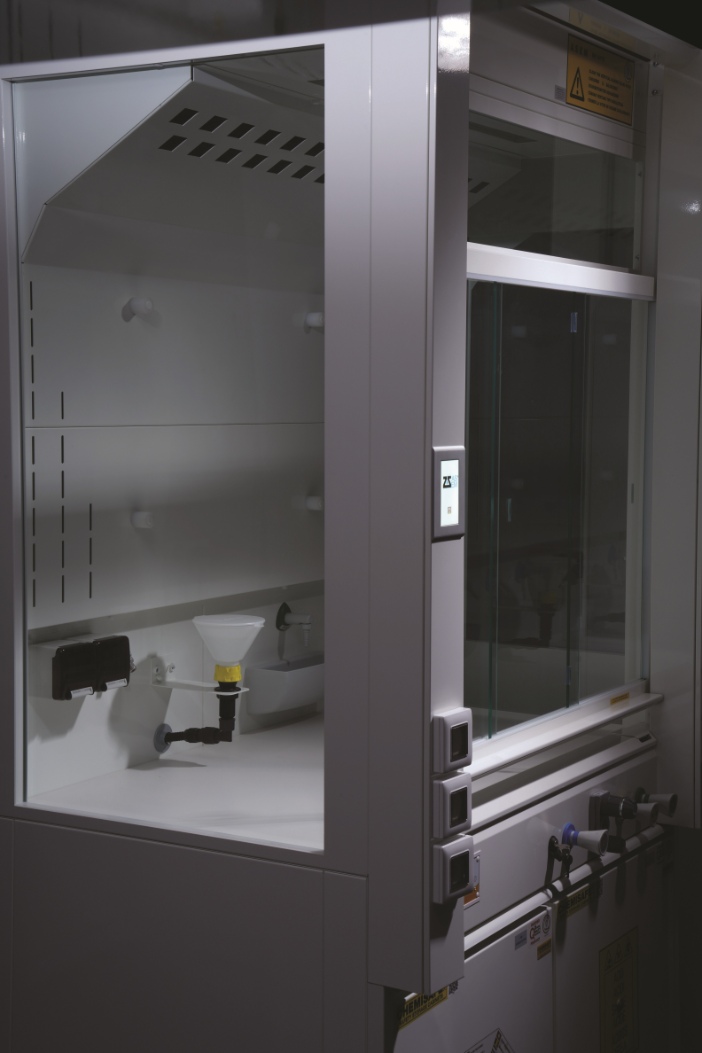

The Asem Kristal L1800 is a premium fume hood combining EN14175 and NFX15-203 certification with a Class 0 galvanized steel frame. It features a vertical counterbalanced sash with laminated glass and anti-fall safety, an integrated sealed technical drawer for utilities and electronics, and a double-plenum system for efficient vapour extraction. This makes it a robust and ergonomic choice for advanced laboratories.

Asem Kristal L1800 Fume Hood – Premium Wide Model with Advanced Safety

The Kristal L1800 represents Asem’s high-end fume cupboard line, engineered for durability, operator safety, and simplified maintenance. Constructed with a Class M0 galvanized steel structure coated in epoxy, it meets both EN14175 and NFX15-203 certifications.

Its vertical sash, built with laminated 6 mm safety glass in three sliding sections, is counterbalanced with an anti-fall security system and guided by low-noise runners. Mechanical stops at 30 cm and 45 cm provide controlled airflow positions. Counterweights and cables are located outside the airflow to avoid corrosion.

A unique feature of the Kristal range is its sealed technical front drawer, which integrates utilities, electrical connections, alarms, and electronics into a protected compartment. This design prevents accidental spills from reaching sensitive components and makes maintenance fast and reliable.

The fume hood incorporates a double rear plenum for heavy and light vapours, by-pass and airfoil-pass airflow systems, and a polycarbonate ceiling panel serving as both a deflagration outlet and a light diffuser. IP65 LED lighting, modular side glazing, and removable panels for cleaning further enhance usability.

Lead time: 8-10 weeks

| Specification | Value |

|---|---|

| External dimensions (W × D × H) | 1865 × 960 × 2300 mm |

| Internal dimensions (W × D × H) | 1800 × 750 × 1230 mm |

| Weight | 330 kg |

| Structure | Full metal, Class M0 |

| Sash | Vertical counterbalanced sash, 3 laminated sliding glass windows |

| Airflow volume at 0.5 m/s | 1288 m³/h |

| Variable volume range | 58–1288 m³/h |

| Economy mode volume range | 58–859 m³/h |

| Pressure loss | 50 Pa |

| Sash locking height | 450 mm (economy at 300 mm) |

| Lighting | LED, IP65, 800 lux, outside aspiration volume |

| Exhaust collar | Ø 250 mm (Ø 200 mm optional) |

| Utilities | Integrated via sealed front technical drawer |

| Safety | Anti-fall sash system, deflagration ceiling panel, technical separation drawer |

| Supports | Trellis support points Ø 12/13 mm (6) |

- Exhaust collar diameter: Ø 200 mm (instead of Ø 250 mm)

- Side panels: full metal or full-height glazed for maximum visibility

- Worktop materials: stoneware, polypropylene, glass, stainless steel

- Interior lining: stoneware, glass, HPL, polypropylene, stainless steel

- Technical drawer configurations for utilities (gas, water, vacuum, compressed air)

- Motorised sash opening system

- External IP55 sockets integrated in technical drawer

- Airflow control systems (AC1000, AC2000, AC3500, AC7000)

- RMP patented mechanical flow regulation system

- Presence sensor with auto-closing sash

- Under-bench furniture: storage cabinets or chemical safety cabinets