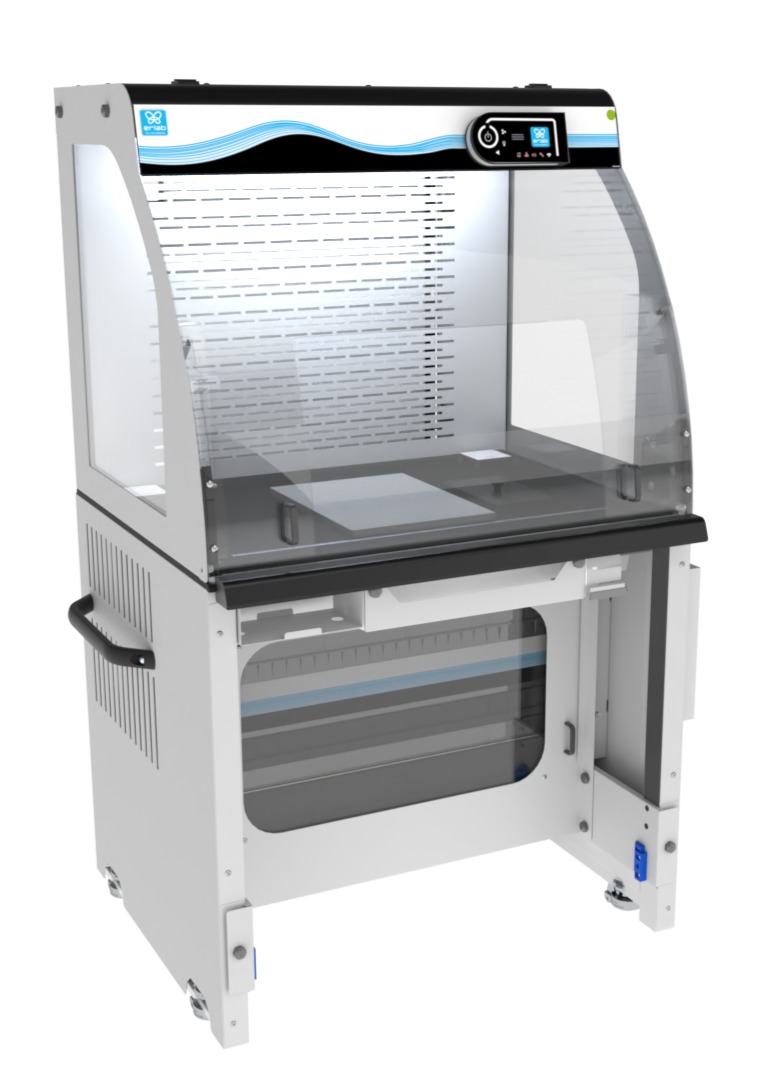

Weighing station, Captair 391, 1,0m

Pricing on request

- Weighing station / balance enclosure

- Internal width: 872 mm

- External width: 1140 mm

- Flexible filtration choices

- BIBO system optional

- Integrated weighing stone and waste compartment

Captair 391 Weighing Station: Precision and Protection in One Balance Enclosure

The Captair 391 Weighing Station is a high-performance balance enclosure designed to ensure both operator safety and weighing accuracy. Ideal for laboratories handling hazardous powders or potent pharmaceutical compounds, this ductless system provides a controlled environment that minimizes airflow turbulence, allowing for precise measurements down to six decimal places.

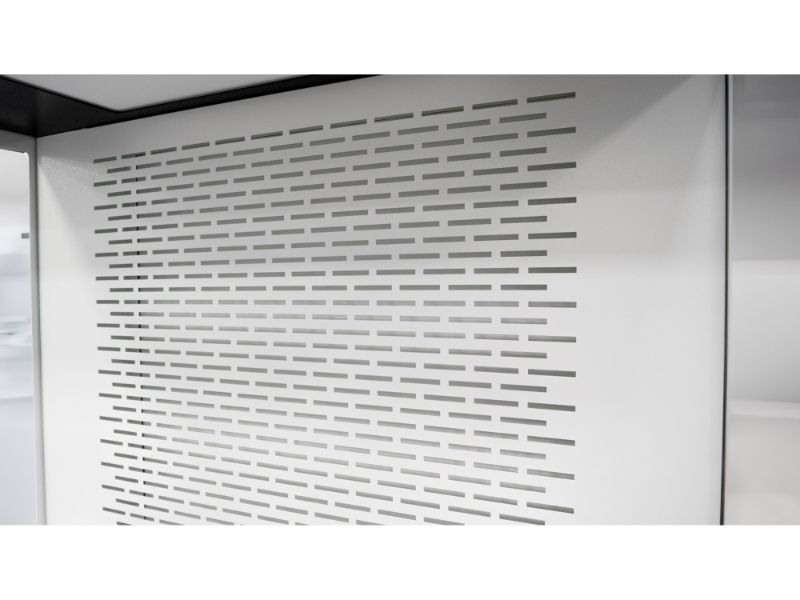

Equipped with Flex Technology, the Captair 391 offers customizable filtration solutions, combining HEPA and optional carbon filters to effectively capture particulates and chemical vapors at the source. This ensures a contaminant-free workspace without the need for external ducting, making installation straightforward and flexible.

The station features Smart Technology™, incorporating real-time monitoring through visual and auditory alerts. The intuitive Smart-Light Communication™ system provides immediate feedback on operational status, including airflow velocity, filter saturation, and fan performance. Additionally, the eGuard app allows for remote monitoring and control, enhancing user convenience and safety.

Certified to meet AFNOR NF X15-211:2009 standards, the Captair 391 ensures compliance with stringent safety regulations. Its ergonomic design, including a slanted sash and spacious interior, offers comfortable access to balances and other equipment, facilitating efficient workflow.

Whether you’re conducting sensitive weighing tasks or working with hazardous substances, the Captair 391 Weighing Station delivers a reliable and safe solution, embodying the perfect balance between precision and protection.

Technical Specifications

| Technical Specifications | Details |

|---|---|

| Safety Standards | AFNOR NF X15-211: 2009; EN 14175-3 |

| Airflow | 210 m³/h (Carbon Filter) – 300 m³/h (HEPA Filter) |

| Air Face Velocity | 0.4 to 0.6 m/s |

| Voltage/Frequency | 110–230V / 50–60Hz |

| Power Consumption | Max. 2300W (with 2 internal outlets) |

| Glass Opening | Oblong (Carbon Filter) or Trapezoidal (HEPA Filter) |

| Structure | Corrosion-resistant electro-galvanized steel, coated with acid-resistant polymer |

| Side and Front Panels | Chemical-resistant acrylic |

| Filtration Module | Polypropylene |

Features

| Features | Details |

|---|---|

| Communication Interface | Simple auditory and visual signals for operating duration, air face velocity, automatic filtration failure alarm, ventilation settings, fan failure alarm |

| Filtration Technology | 1 adaptable filtration column (with BIBO secure filtration unit*) |

| Carbon Filtration for Gases and Vapors | Depending on the configuration of the filtration column |

| Particulate Filtration for Powders | Depending on the configuration of the filtration column |

| Monitoring | Real-time monitoring of safety parameters |

| Ambient Conditions Monitoring | Temperature (°C) / Humidity (RH) sensors |

| Interior Lighting | LED lighting > 650 lux |

| Anemometer | Air face velocity alarm / air face velocity indicator |

| List of Chemicals | Over 700 approved chemicals compliant with AFNOR NF X15-211 |

| Ceiling Lighting | ON/OFF button |

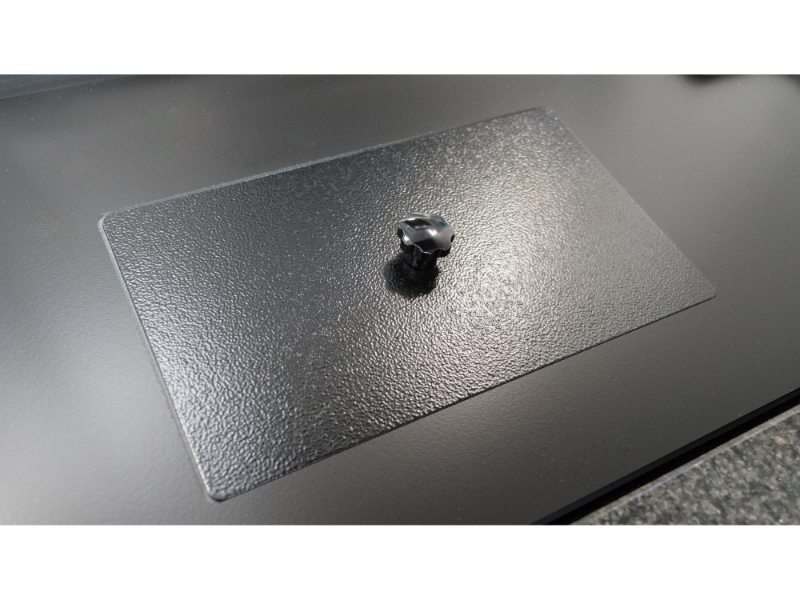

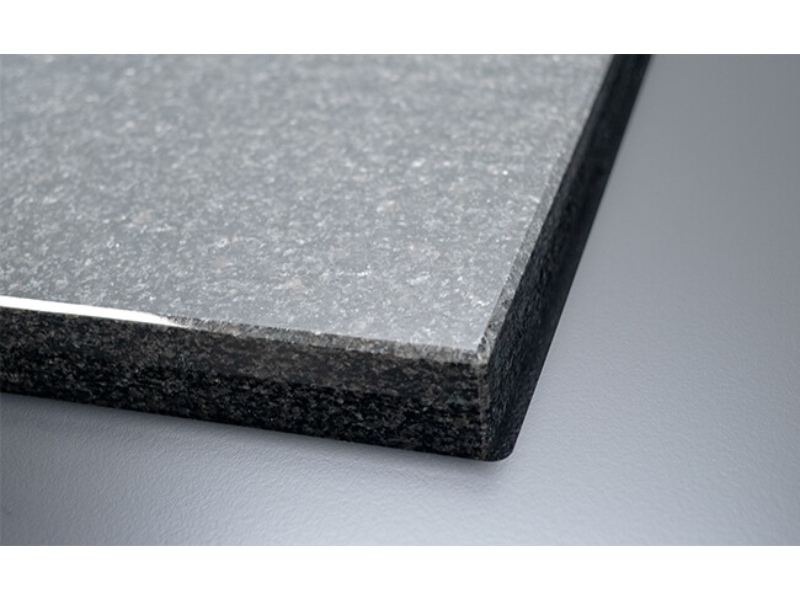

| Worktop | Trespa® Top Lab PLUS |

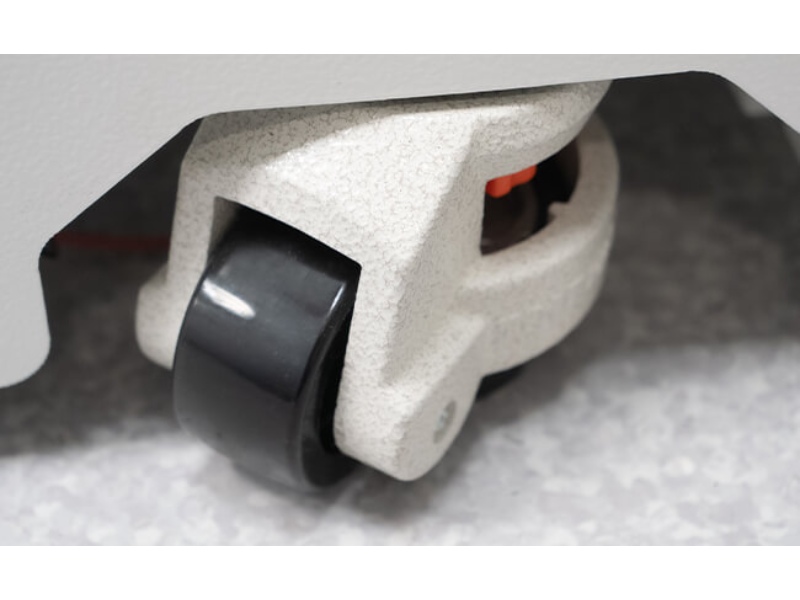

| Workbench | Mobile (installation) and Fixed (with anti-vibration rubber casters) |

| Note | *BIBO = Bag In / Bag Out system |

Filter configuration

- 1C Liquid chemicals

- 2C Liquid chemicals (main + safety filters)

- 1C1P Liquid chemicals in cleanrooms

- 2C1P Liquid chemicals in cleanrooms (with safety filter)

- 1P Powders only (optional Bag-In-Bag-Out system (BIBO) for HEPA)

- 1P1C Liquid and solid chemicals (optional Bag-In-Bag-Out system (BIBO) for HEPA)

- 1P2C Liquid and solid chemicals (main + safety filters) (optional Bag-In-Bag-Out system (BIBO) for HEPA)

- 1P1C1P Liquid and solid chemicals in cleanrooms (optional Bag-In-Bag-Out system (BIBO) for HEPA)

- 2P Powders only (optional Bag-In-Bag-Out system (BIBO) for HEPA)

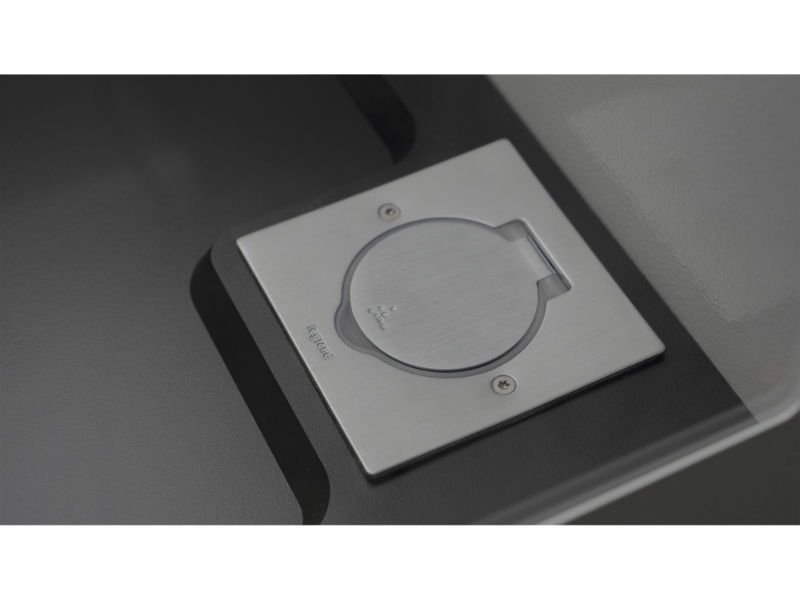

Molecode Detection sensor for applications with liquid chemical

- Type A for Acids

- Type F for Formaldehyde

- Type S for Solvents

weighing stone/ weighing

- MARBLE (standard)

- Stainless Steel (option)