Laminar Flow Cabinets & Hoods for Sterile Lab Environments

Labman Instruments is official distributor for CleanAir by Baker laminar flow cabinets and biological safety cabinets for Belgium.

Baker Laminar Flow Cabinets – Clean Benches for Sterile Work

Laminar flow cabinets, also known as laminar flow hoods or clean benches, are designed to create a sterile, particle-free workspace by directing filtered air in a uniform laminar stream across the work surface. These enclosures use HEPA or ULPA filters to remove airborne contaminants from ambient air, ensuring an ISO Class 5 (Class 100) clean environment inside the cabinet. The result is a consistent, unidirectional airflow that generates positive pressure, effectively preventing unfiltered air or particulates from entering the work zone.

Laminar flow cabinets are ideal for protecting products or samples, but they do not protect the user or the environment. Therefore, they are not suitable for handling biological agents or hazardous chemicals.

For work involving biohazardous materials, see our biosafety cabinet solutions. For chemical handling, we recommend our ducted or ductless fume hoods.

-

For biohazardous materials, please visit our biosafety cabinet page.

-

For hazardous chemicals, we recommend our fume hoods instead.

Horizontal laminar flow cabinets

Horizontal Laminar Flow Cabinets

The HEPA filter is located at the back of the cabinet, and clean air flows horizontally toward the front opening. This design minimizes turbulence on the work surface and is often preferred for instrument assembly or non-hazardous powder handling.

- Horizontal laminar flow bench

- Internal width: 1249 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Air cleanliness: ISO Class 5/ GMP Class A conditions

Price on request

- Horizontal laminar flow bench

- Internal width: 1859 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Air cleanliness: ISO Class 5/ GMP Class A conditions

Price on request

- Horizontal laminar flow bench

- Internal width: 1554 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Air cleanliness: ISO Class 5/ GMP Class A conditions

Price on request

Vertical laminar flow cabinets

Vertical Laminar Flow Cabinets

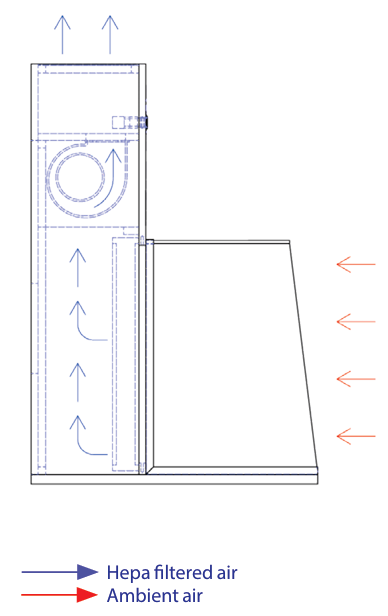

In this setup, the HEPA filter is positioned at the top of the cabinet, and air flows vertically down onto the work surface. This type is commonly used when vertical space is limited or when vertical airflow is more ergonomic for the task.

- Vertical laminar flow bench

- Internal width: 885 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Sash: vertical sliding sash

Price on request

- Vertical laminar flow bench

- Internal width: 1190 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Sash: vertical sliding sash

Price on request

- Vertical laminar flow bench

- Internal width: 1495 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Sash: vertical sliding sash

Price on request

- Vertical laminar flow bench

- Internal width: 1800 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

- Sash: vertical sliding sash

Price on request

Frequently asked questions

What is a laminar flow hood?

What is the difference between a laminar flow cabinet and a biosafety cabinet?

Do laminar flow cabinets require certification in Belgium?

When should I use a horizontal vs vertical laminar flow cabinet?

Use a horizontal laminar flow cabinet when working with small, light instruments or materials that require minimal turbulence, such as petri dishes or pipettes. When there is no risk for turbulence, horizontal laminar flow hoods are superior because the horizontal flow blows potential contaminations towards the work opening and allows working closer to the HEPA filter. Vertical laminar flow cabinets are better for taller equipment or processes with more airflow clearance.

Is a laminar flow cabinet safe for handling chemicals?

What ISO class is a laminar flow cabinet?

Most laminar flow cabinets provide ISO Class 5 clean air, equivalent to Class 100 (US FED STD 209E). This means fewer than 100 particles ≥0.5 microns per cubic foot of air, suitable for sterile lab procedures, electronics, or pharmaceutical preparation. When placed inside a cleanroom environment, air quality can reach ISO Class 3 clean air.

Where can I buy a certified laminar flow hood in the BeNeLux?

You can purchase certified laminar flow cabinets and clean benches in Belgium, Netherlands, and Luxembourg through Labman Instruments, official distributor of Baker CleanAir solutions. We offer expert advice, installation, and service support across the BeNeLux region.