Powder hoods

Labman Instruments is official distributor for CleanAir by Baker and Erlab powder hoods and other laboratory cabinets.

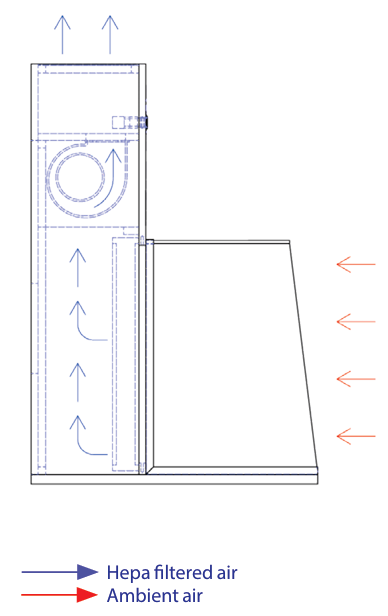

The principle of NEG Series powder extraction hoods or balance enclosures is based on HEPA filtration of the extracted air. Ambient air is extracted from the environment into the work area of the laboratory cabinet. The HEPA filter at the back of the work area filters the extracted air, in order to offer personnel and environmental protection. Pre-filters capture the bulk of the larger particles to reduce operating cost.

General features

- Energy saving EC fans

- Low sound level

- HEPA filter H14 (efficiency of 99,995% MPPS)

- Pre-filter (efficiency of 80 – 90% Am)

- HEPA- and pre-filter easy replacable

- Easy to operate via the front of the cabinet –

- Switch (on/off) – Stepless variable (0-100%) speed control

- Tempered safety glass side windows

- Laminate body

- Pre-filter positioned in front of HEPA filter, increasing the lifetime of the HEPA filter

Special features

- Available with or without worktop. A cabinet without worktop can be used in combination with a weighing stone Safety features

- Fan free of contamination because of it’s position behind the HEPA and pre-filter

- HEPA filter and pre-filter surface covers complete work area, ensuring optimal air extraction

- Smooth interior for efficient and easy cleaning

CleanAir by Baker NEG series powder extraction hoods

NEG Series powder hoods are standard available in sizes 60, 90, 120, 150 and 180 cm. Different sizes on request. NEG AP Series powder hoods designed for pharmacies and other rooms with limited space. NEG AP Series has reduced height and depth. NEG AP Series is standard available for size 60 cm and 100 cm. All models are available with or without worktop.

- Powder hood/balance enclosure

- Internal width: 627 mm

- Internal depth: 370 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 583 mm

- Internal depth: 450 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 888 mm

- Internal depth: 450 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 975 mm

- Internal depth: 370 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 1193 mm

- Internal depth: 450 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 1498 mm

- Internal depth: 450 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

- Powder hood/balance enclosure

- Internal width: 1803 mm

- Internal depth: 450 mm

- Main filter: HEPA filter: H14 conforms to EN 1822

- Pre-filter: Coarsefilter (ISO 16890)

Price on request

Erlab Captair 391 weighing station

The Erlab Captair 391 weighing station or balance enclosure is the ideal solution when doing precision weighing of hazardous products. Design features like Trespa worktop and integrated weighing stone give a vibration free environment, allowing accurate weighing up to micro ( 10 -6g) levels.

Frequently asked questions about powder hoods

How does a powder hood work and when should I use one?

Powder hoods use a ventilator to pull the air from the workstation through a pre-filter and a HEPA filter. All particles released during the handling of the hazardous powders get captured by the filters before the air is recirculated back into the laboratory. This means that the work area is continuously under negative pressure, creating an air flow away from the operator.

Guidance on when a ventilated hood should be used, can typically be found in the safety datasheets of the products. When the datasheet advises to handle the product in a ventilated enclosure, powder hoods can be used. If it is required to handle the product in a clean environment, a biological safety cabinet or a cytotoxic cabinet can be used.

What’s the difference between a powder hood and a standard fume hood?

A powder hood or powder weighing cabinet is intended to work with only hazardous powders and does not capture any chemical vapors. Powder hoods recirculate the filtered air back to the room, like ductless fume hoods. Because they are not connected to any HVAC system, the air flow is very stable, making it very suitable for application sensitive to pressure fluctuations, like weighing.

Standard fume hoods are connected to the HVAC systems, sending the air outside the building. Standard ducted fume hoods are more focused on protection against chemical vapors, coming from solvents, acids and bases. Powders chemicals don’t go well together with HVAC systems, because they tend to pile up in curves due to centrifugal force. The connection of the HVAC system also translates in a much less stable air flow, making ducted fume hoods less suitable for applications like weighing.

How often does the filter in a powder cabinet need to be replaced?

Filter lifetime depends largely on the air cleanliness and the usage. A powder hood placed in a cleanroom environment will have a much longer filter lifetime than a powder hood placed in a production environment.

Prefilters capture the bulk of the larger particles. They have a low cost and are typically replaced annually.

HEPA filters are more expensive, and are typically replaced when the air speed starts to drop and the powder hood air speed alarm is triggered. HEPA filter lifetime in powder hoods typically range between 5-12 years.