Biological safety cabinets

Labman Instruments is official distributor for CleanAir by Baker Biological Safety Cabinets (BSC) and laminar flow cabinets (LAF) for Belgium.

Reliable microbiological safety cabinets for optimal product and personnel protection

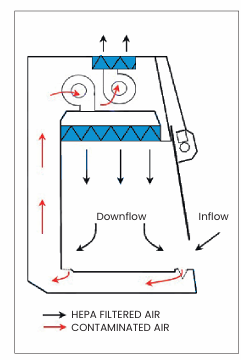

In laboratory environments, the term biosafety cabinet most commonly refers to a Class II Type A2 biological safety cabinet. This model provides operator, product, and environmental protection, making it ideal for microbiological work involving pathogenic agents. The filtered airflow is partially recirculated within the cabinet and partially exhausted back into the laboratory, ensuring a sterile work zone while maintaining lab safety. Due to its versatility and compliance with most biosafety requirements, the Class II A2 is by far the most widely used biosafety cabinet type in clinical, research, and pharmaceutical settings.

When working with significant volumes of volatile chemicals or radionuclides, a Class II Type B2 biosafety cabinet is preferred. This configuration provides 100% external exhaust through a hard-ducted connection to the building’s HVAC system, eliminating the possibility of chemical accumulation or recirculation inside the workspace.

For high-containment laboratories, such as those operating at biosafety level 4 (BSL-4), or when absolute physical containment is required, a Class III biosafety cabinet is mandated. These gas-tight enclosures operate under negative pressure and are accessed via attached gloves, offering the highest level of personnel and environmental protection.

All biosafety cabinets must comply with the EN 12469:2000 standard — the European benchmark for microbiological safety cabinets. This standard defines the performance criteria for three cabinet classes: Class I, Class II, and Class III, ensuring consistent containment, filtration efficiency, and operational safety across all certified units.

Biological safety cabinets with manual sash

- Biosafety cabinet class II type A2

- Internal width: 875 mm

- Compliance: compliant to EN12469

- Motors: 2 x energy efficient EC motors

- Sash type: manual sliding sash

Price on request

- Biosafety cabinet class II type A2

- Internal width: 1180 mm

- Compliance: TÜV Nord certified to EN12469

- Motors: 3 x energy efficient EC motors

- Sash type: manual sliding sash

Price on request

- Biosafety cabinet class II type A2

- Internal width: 1485 mm

- Compliance: compliant to EN12469

- Motors: 3 x energy efficient EC motors

- Sash type: manual sash

Price on request

- Biosafety cabinet class II type A2

- Internal width: 1790 mm

- Compliance: TÜV Nord certified to EN12469

- Motors: 5 x energy efficient EC motors

- Sash type: manual sash

Price on request

Biological safety cabinets with electrical sash

- Biosafety cabinet class II type A2

- Internal width: 1180 mm

- Compliance: TÜV Nord certified to EN12469

- Motors: 3 x energy efficient EC motors

- Sash type: electrical sash

Price on request

- Biosafety cabinet class II type A2

- Internal width: 1485 mm

- Compliance: compliant to EN12469

- Motors: 3 x energy efficient EC motors

- Sash type: electrical sash

Price on request

- Biosafety cabinet class II type A2

- Internal width: 1790 mm

- Compliance: TÜV Nord certified to EN12469

- Motors: 5 x energy efficient EC motors

- Sash type: electrical sash

Price on request

Frequently asked questions

What is a biological safety cabinet and how does it work?

A biological safety cabinet (BSC) is a ventilated enclosure designed to protect laboratory personnel, the environment, and samples from biohazardous agents. It uses directional airflow and HEPA filtration to create a controlled, sterile working environment while preventing the escape of potentially harmful aerosols generated during microbiological procedures.

What is a biological safety cabinet, and how does it differ from a laminar flow cabinet?

Biosafety cabinets (BSCs) are designed to protect the user and the environment from exposure to biohazards. Biological safety cabinets class II and III also protect the product/experiment against crosscontamination. In contrast, laminar flow cabinets primarily protect the product but do not offer protection to the user or the environment against the used products.

When should a laboratory use a Class II biological safety cabinet?

Class II BSCs are essential when working with low- to moderate-risk biological agents (BSL-1 to BSL-3), particularly when aseptic conditions are required — for example, in microbiology labs, tissue culture, pharmaceutical compounding, and virology research. They ensure product sterility while protecting personnel and the surrounding environment. For handling high risk biological agents (risk group 4 micro-organisms), a class III biological safety cabinet is advised.

What are the different classes of biological safety cabinets, and which one should I use?

here are three main classes:

-

Class I: Protects the user and environment but not the product.

-

Class II: Protects the user, environment, and product; commonly used in microbiological work.

-

Class III: Provides the highest level of protection; used for handling high-risk pathogens.

A class I cabinet is barely used. The biosafety cabinet class II A2 is by far the most used cabinet type in Europe. Mainly because there are little applications involving biohazards that don’t require product/experiment protection against cross-contaminants from the environment. Also the price of a biosafety cabinet class I cabinet is very similar to the price of a biological safety cabinet class II A2, which offers offers the product protection in addition to the user and environment protection. A class III cabinet offers the highest level of containment, but comes with a higher pricing and includes additional steps in the workflow (for example material ingress via an air lock). Therefore a biosafety cabinet Class III is typically only used in biosafety level 4 laboratories.

Can a BSC be used for chemical vapors or toxic fumes?

Biological safety cabinets (BSCs) are primarily designed for protection against biological agents — not chemical vapors. If chemical handling can be separated from biological work, a fume hood is the safer and recommended solution.

However, in workflows where chemical vapors and biohazards are used together, limited use of low-toxicity chemicals with minimal evaporation may be acceptable inside a Class II A2 BSC, provided it is:

-

Ducted to the HVAC system, or

-

Equipped with an activated carbon filter for chemical filtration.

For procedures involving larger volumes of volatile, flammable, or toxic chemicals, a Class II A2 cabinet is not suitable due to its 70% air recirculation design. In such cases, a Class II B2 BSC with 100% external exhaust is strongly recommended to ensure operator and environmental safety.

Not sure which biosafety cabinet is right for your application?

Contact us for expert, obligation-free advice tailored to your lab workflow.

Do I need to wear additional personal protective equipment (PPE) when working in a biological ssafety cabinet?

Yes, appropriate PPE, such as gloves, lab coats, and eye protection, should be worn to ensure safety, even when working within a biosafety cabinet.

For aerosol-generating manipulations involving certain pathogenic organisms of risk group 3 in high concentrations—organisms that can enter through the respiratory tract, or the mucous membranes of the eyes, nose, and mouth—it is also advisable to wear a respiratory mask or facial protection.

How should I properly use a biological safety cabinet to maintain safety and sterility?

Best practices include:

- Do not place any materials on the air grids. The Biovanguard biosafety cabinets have been designed with inclined back grid and V-shaped front grid to avoid material placement on the air grids.

-

Avoiding overcrowding inside the cabinet.

-

Avoid using Bunsen burners, as they can disturb the downflow. When a Bunsen burner is required: try to only use it for very short periods (for example by using a food pedal).

-

Minimizing rapid movements to prevent airflow disruption.

-

Regularly disinfecting surfaces before and after use

What should I do if there's a spill inside the biological safety cabinet?

Immediately stop work, keep the cabinet running, and follow your laboratory’s spill response protocol, which typically includes:

-

Wearing appropriate PPE.

-

Covering the spill with absorbent material.

-

Applying disinfectant.

-

Cleaning and disposing of waste properly.

How often should biological safety cabinets be certified?

In most laboratory settings, BSCs must be certified at least once a year, or whenever they’re moved, serviced, or modified. Certification ensures that airflow velocities, filter integrity, and containment meet ISO or EN standards.